Knowledge Centre

-

Service the SWR Way

-

At SWR we are committed to providing high levels of customer service, whilst constantly looking at ways in which we can improve your experience in dealing with us. We have a dedicated team on hand to guide you in your selection of the most suitable balustrade system for your project.

Designing and installing your balustrade system is easier than you may think. Simply send us your sketches, photographs or technical drawings and we will help you turn your vision into a reality.

Our aim is to provide you with a premium quality, safe and reliable system. We will guide and advise you based on the industry standards and building regulations to ensure complete peace of mind in your selection.

-

-

Specification & Quote

-

The SWR team is always on hand to assist you with your requirements.

Whether you have architects' drawings, technical drawings or just a free hand sketch we will be happy to support you when deciding which design would suit your project and what components you need to achieve this.

Our in house experts can use your technical drawings and we support most major file formats. From this we can then produce an accurate quotation for you. This service is completely free with no hassle or obligations.

-

-

Stainless Steel Grade Selection

-

Our balustrade range comprises of AISI 304 and AISI 316 stainless steel, both of which are available in a 320 grit brushed satin finish or a mirror polished finish.

AISI 304 and 316 stainless steel appear the same but perform very differently depending on the surrounding environment. This is due to the differences in the chemical composition between the two grades with AISI 316 offering more resistance to corrosion due to the molybdenum content.

In line with industry guidelines, as a general rule we recommend AISI 316 for outdoor use and AISI 304 for interior projects.

Although satin and mirror polished contain the same chemical composition, they appear very different due to the final surface finish. The mirror finish is polished down to approximately 0.2 microns, which produces a very smooth and reflective surface, making it the most suitable finish for coastal and busy industrial areas containing high emissions. Unlike the satin finish, which is polished down to approximately 0.5 microns, mirror polished provides minimal areas for corrosive elements in the air to rest, which potentially cause permanent damage to your system.

The table below can be used as a rough guide to which grade/finish is appropriate for certain environments.

View Material GuideStainless Steel Grades & Finishes Grade Rural Urban Industrial Coastal Internal External Internal External Internal External Internal External Satin 304 ✔ ✘ ✔ ✘ ✘ ✘ ✘ ✘ Satin 316 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✘ Mirror 304 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✘ Mirror 316 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

-

-

Quality Assured

-

As an ISO 9001:2008 approved company, quality is at the forefront in all that we do. We have worked to ensure our balustrade systems are designed and manufactured to comply with industry standards and regulations.

-

-

Loading & Building Regulations

-

With any project the importance of safety has to be at the forefront of our minds when considering the most suitable balustrade system. With this mentality we work closely with our clients, providing advice on loading and dimensional specifications in line with The Building Regulations K2 Document. Our systems have been rigorously tested to BS 6180 and have been fully approved for residential and commercial projects.

Our Glass Channel & Juliet Balconies test reports can be viewed below. Just click on the relevant fixing:

Pure Vista

Pure Vista

POSIglaze

Base Fixed Channel

Base Fixed Channel

TL-6020 Side Fixed Channel

Side Fixed Channel

TL-6021 Glass Juliet Balconies

Glass Juliet Balconies

SkyFORCEOur Modular System test reports can be viewed below. Just click on the relevant system diameter:

-

-

Glass Requirements

-

SWR’s approach to safety is paramount which equally extends to our choice of glass as an infill solution for your balustrade system. All glass supplied by SWR is manufactured in accordance with BS EN 12600:2002 and our dedicated team will work closely with you to determine the best glass option for you based on the load information you provide.

We recognise that clients need a ‘one stop’ solution when it comes to purchasing a glass infill balustrade and so SWR has established a partnership with a leading glass processor who has been supplying safety glass since 1985 and is a leading supplier of quality architectural glass products throughout the U.K.

Whether your requirement is for a domestic glass balustrade for your patio or balcony or a large commercial development, we can supply toughened or toughened & laminated glass to suit your needs.

Choosing the Right Glass for You

When you contact SWR with your glass enquiry, our experienced and helpful team will determine the right glass for you. We will ask some key questions about your requirement which will enable us to discuss the various options with you:

- Height of the glass you require

- Placement of the glass balustrade (internal or external)

- Is a stainless steel handrail required

- The loading the glass balustrade needs to achieve – this can be provided by a structural engineer or your local building control officer

Once we have established this information, we can discuss what thickness of glass will be required and whether this will be provided as toughened, heat soaked glass or toughened and laminated glass. Toughened glass is ideally suited to most applications where safety is critical, but consideration should be taken if the glass balustrade is at a high level.

Toughened & laminated glass is constructed of two pieces of toughened glass either side of a laminate interlayer and offers the same strength under impact as toughened glass with a crucial safety difference - If the pane is damaged resulting in the glass breaking, the fragments will be retained by the laminate interlayer, enabling the system to still act as a barrier until a replacement can be installed.

As your glass balustrade will not only need to look great it is also designed to be a key safety feature in your environment. As safety is paramount to SWR, we can call upon the services of an industry recognised Structural Glass Consultancy who, from the information provided to them, can determine precisely what type of glass is required to achieve the strength it is intended for. For your piece of mind, they can provide a written report detailing the calculations used to determine this.

The glass delivered to you will have polished edges and radius corners as standard unless otherwise asked for. We can also supply frosted/sandblasted glass, silkscreen printed glass as well as etched glass and drill holes up to 30mm diameter – ask our friendly team for more information.

Quality Assured Glass Production

As with many products that are available to today's consumer, toughened glass is available from 'KITE MARK' approved suppliers. The product standard that covers this area is BS EN 12150, impact performance requirements for flat safety glass and safety plastics for use in buildings. BS EN 12150 a Kite Marked product standard, which means that a manufacturer of the product may chose to adhere to the regulations and guidelines that are specific to that Kite Mark scheme. The British Standards Institute controls the Kite Mark License scheme, and is responsible for audits and testing regimes. Only when satisfied that a particular product is satisfactory, and that manufacturing controls are in place to ensure continuous compliance, will a Kite Mark License be granted. Kite Mark Licenses are issued for each product type, i.e. a manufacturer may process and supply a wide range of thicknesses of toughened glass, but only have a Kite mark license for one. SWR Supplied glass, all glass thicknesses, tints and finishes are included on the Kite Mark License scope. Continuous assessment and monitoring of production methods and working practices ensure that SWR’s glass partner provide a fully compliant product to our customers in the market place.

-

BS EN 12150 Glass in building - Thermally toughened soda lime silicate safety glass

-

BS EN 14179 Glass in building - Heat soaked thermally toughened soda lime silicate safety glass

-

BS EN 14449 Laminated glass and laminated safety glass

Delivery of glass

SWR can arrange to have your glass delivered to the majority of locations on the UK mainland. By using a dedicated courier for your glass, we can ensure your order arrives safely and in perfect quality for use in your balustrade system.

The cost of the delivery will be determined by the location of where it is required. This will be advised to you at the time of your enquiry.

PLEASE NOTE: There must be at least 2 people available to accept & handle the delivery. The delivery driver can only offload from the lorry and pass to you - They will not carry/transport the glass any further.

-

-

Cutting, Drilling and Finishing

-

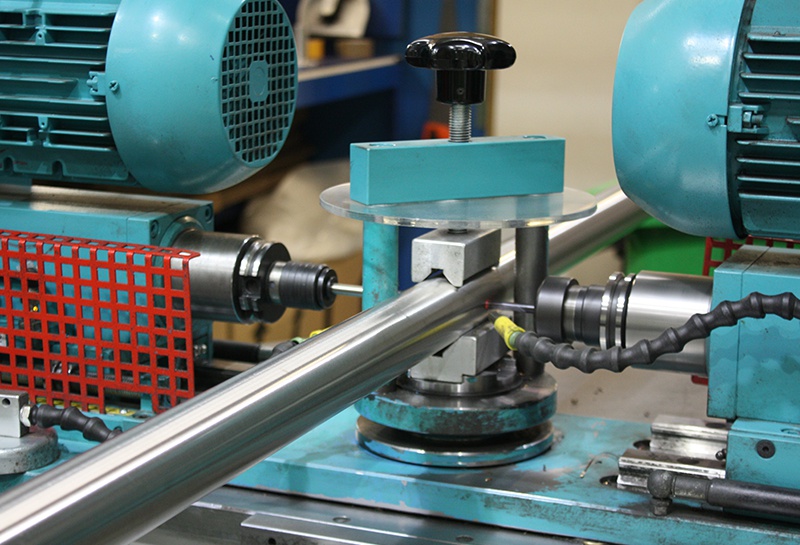

SWR offer a full cutting, drilling and polishing service. Our design technicians provide our engineers with technical drawings of your system, designed to your specifications. Our highly skilled engineers then cut, drill and tap the balustrade accordingly.

During production of your system we take care to polish each tube giving it a smooth clean finish ready for on site assembly.

In line with our ISO 9001:2008 procedures we carry out rigorous checks throughout the production process to ensure ease of use and simple assembly when on site.

For your convenience on site we work to package each part so that all are marked up clearly and can be easily identified when unpacking and preparing to start the job. It’s the small details that make the difference and ultimately help you to safely and efficiently install your balustrade system.

-

-

Cleaning & Maintenance

-

An important thing to remember with stainless steel is that it is stain ‘less’ and not stain ‘free’. Stainless steel is not completely corrosion proof and does require on-going cleaning and maintenance. As members of the British Stainless Steel Association we advise all of our customers to carry out necessary maintenance on your system to help retain the modern finish of the product.

We supply our own cleaning product specifically designed for stainless steel. Our cleaner gives a sparkling appearance leaving a protective film to aid in future maintenance.

Descriptions Size Part Code SWR Easy Clean - Interior Balustrade Cleaner 750ml 0000.90.015 SWR Metal Shine - Exterior Balustrade Cleaner 750ml 0000.90.020

Stainless Steel Materials

Warranty:

SWR guarantees balustrade will meet BS6180 when installed to match our test report

Any faulty goods provided by SWR will be investigated and replaced where manufacturing has proven faulty

Warranty will only be apply if system is cleaned regularly and stored / installed in the proper manor

Composition:

All Stainless Steel products are manufactured and tested to 320grit and are tested using a spectrometer in house.

Our Balustrade will be supplied either in an AISI 304 or 316 grade stainless steel

Tolerances:

All tolerances will meet BS6180

Maintenance Instructions:

Requirement Suggested Method Comments Routine cleaning of light soiling Soap, detergent or dilute (1%) ammonia solution in warm clean water. Apply with a clean sponge, soft cloth or soft-fibre brush then rinse in clean water and dry Satisfactory on most surfaces Fingerprints Detergent and warm water, alternatively, hydrocarbon solvent Proprietary spray-applied polishes available to clean and minimise remarking Oil and grease marks Hydrocarbon solvents (methylated spirit, isopropyl alcohol or acetone) Alkaline formulations are also available with surfactant additions e.g.'D7' Polish Stubborn spots, stains and light discolouration. Water marking. Light rust staining Mild, non-scratching creams and polishes. Apply with soft cloth or soft sponge and rinse off residues with clean water and dry Avoid cleaning pastes with abrasive additions3. Suitable cream cleansers are available with soft calcium carbonate additions, e.g. 'Jif', or with the addition of citric acid, e.g. Shiny Sinks1. Do not use chloride solutions Localised rust stains caused by carbon steel contamination Proprietary gels, or 10% phosphoric acid solution (followed by ammonia and water rinses), or oxalic acid solution (followed by water rinse). Small areas may be treated with a rubbing block comprising fine abrasive in a hard rubber or plastic filler. Carbon steel wool should not be used, nor should pads that have previously been used on carbon steel. A test should be carried out to ensure that the original surface finish is not damaged. Heating or heavy discolouration a) Non-scratching cream or polish e.g. Solvol Auto Chrome Metal Polish

b) Nylon-type pad, e.g. 'Scotchbrite'a) Creams are suitable for most finishes, but only use 'Solvol' on bright polished surfaces. Some slight scratching can be left.

b) Use on brushed and polished finishes along the grain.Badly neglected surfaces with accumulated grime deposits A fine, abrasive paste as used for car body refinishing, e.g. 'T-cut' rinsed clean to remove all paste material and dried May brighten dull finishes. To avoid a patchy appearance, the whole surface may need to be treated. Paint, graffiti Proprietary alkaline or solvent paint strippers, depending upon paint type. Use soft nylon or bristle brush on patterned surfaces. Apply as directed by manufacturer.

Notes:

1. The products referenced in this information sheet are understood to be suitable for stainless steels. However, no endorsement of the products or their manufacturers is implied and it is acknowledged that other manufacturing companies may provide products of equal or better quality. The following companies manufacture proprietary names mentioned: - 'Jif' - Lever Brothers Ltd, 'Shiny Sinks' - Home Products Ltd, 'Ajax' - Colgate Palmolive Ltd, 'D7 Stainless Steel Polish' - Diversey Ltd, 'T-Cut' - Automotive Chemicals Ltd and 'Solvol Auto Chrome Metal Polish' - Hammerite Products Ltd

2. Cleaning agents should be approved for use under the relevant national environmental regulations and, in addition, prepared and used in accordance with the manufacturers or suppliers' health and safety instructions. Solvents should not be used in enclosed areas.

3. Nylon abrasive pads should be adequate for dealing with most deposits. If a more severe treatment is needed to mask coarse scratches or physical damage on a surface, use the finest abrasive medium consistent with covering the damage marks. With directional brushed and polished finishes, align and blend the new "scratch pattern" with the original finish, checking that the resulting finish is aesthetically acceptable. Silicon carbide media may be used, especially for the final stages of finishing. Avoid using hard objects such as knife blades and certain abrasive/souring agents as it is possible to introduce surface scuffs and scratches. Scratching is particularly noticeable on sink drainer areas. These are usually superficial and can be removed with proprietary stainless steel cleaners or, alternatively, with a car paint restorer, such as 'T-cut'.

4. If wire brushes are used, these should be made of a similar or better grade of stainless steel. Ensure that all abrasive media used are free from sources of contamination, especially iron and chlorides.

5. When cleaning a surface with any chemical preparation or abrasive medium, a trial should be done on a small, unobtrusive hidden or non-critical area of the surface, to check that the resulting finish matches with the original.

6. To avoid water marks, use clean rinsing water, such as reasonable quality potable (tap) water. Drying marks may be avoided using an air blower or wiping with clean disposable wipes.

7. Rust marks or staining on stainless steels is unlikely to be the result of corrosion to the stainless steel itself (similar marks may also be found on porcelain and plastic sinks). These marks are likely to result from small particles of carbon steel from wire wool.Aluminium Materials

10 Year Warranty:

All aluminum profiles delivered by ONLEVEL meet the European standard EN755-2 on mechanical properties.

ONLEVEL guarantees that the profile will retain these mechanical properties for at least 10 years if they are handled in a proper way whereby the following circumstances are prevented:

• Exposure to temperatures above 150 degrees Celsius

• Extreme bending forces (to avoid fatigue fractures)

• Exposure to extreme corrosive conditions

Guarantee only applies if the products are regularly (depending on climate class) and professionally cleaned, see maintenance instructions below.

Composition:

All aluminum profiles delivered by ONLEVEL meet European standard EN573-3 for chemical composition. All glass profiles are produced from alloy 6063-H T6, the rest of the profiles from alloy 6063-T5.

Tolerances:

All tolerances are accordance with normative 12020-2.

Maintenance Instructions:

Periodically cleaning will prevent a negative effect on the anodization layer. Anodizing layers are sensitive to acids, salts and other aggressive substances and wear out faster. In addition, thick dirt layers absorb more moisture and increases the corrosion of the anodizing surface.

Cleaning method:

Use of soft cleaning materials with no abrasive effect, such as cotton (do not use, steel wool or sandpaper etc.).

Use a neutral non-abrasive and PH-neutral (pH 6-8) cleaning agent. Do not use solvents (petrol, acetone), alkaline products (ammonia, sodium), acid products (sulfuric acid, acetic acid)

Rinse parts after cleaning carefully with plenty of fresh water. Sea salts must be removed as soon as possible.

Visually inspect the anodized layer after cleaning for areas where the integrity of the protective anodization layer is breached, in these areas professional restoration of the anodization layer is needed.

Cleaning interval:

Climate clas Indoor C2/C3 outdoor C2/C3 outdoor no rain C4/C5 outside coastal area C4/C5 outside coastal area no rain Aluminum anodized Every year Every 6 months Every 6 months Every 4 months Every 2 months

-